Someone recently asked how I packed fabric for international shipping. While most fabric is shipped on the core, Aneta recently ordered several fabrics that needed to be boxed as they were going to be shipped in a container. I thought it was a good time to show what is needed for getting the fabric ready.

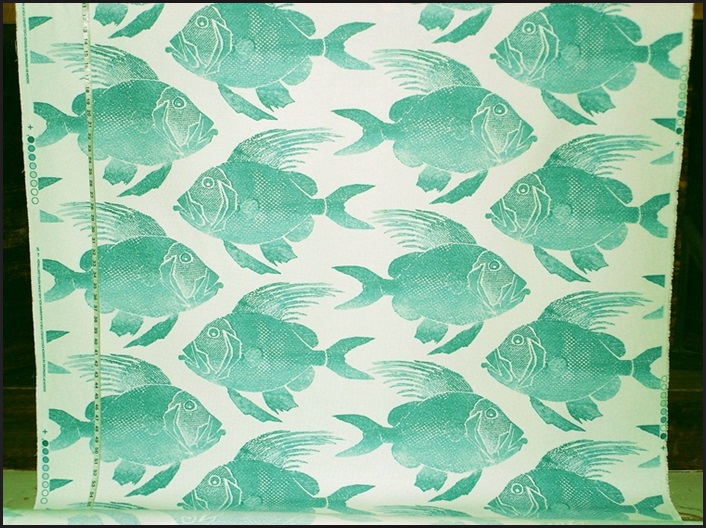

Aneta needed 17 yards of the new

indoor/outdoor fish fabric.

INDOOR/OUTDOOR FISH FABRIC

First a box is chosen.

The size depends on the amount of fabric that is to be shipped.

I use 100 lb. test boxes to withstand anything except an elephant sitting on it.

Then the correct bolt is pulled, and the fabric is measured.

I use a rather unique zig-zag folding method

that I developed which allows for the maximum amount of fabric

to be gotten into the minimum amount of space.

Clamps are used to ensure the folds are sized correctly,

and to keep the fabric from shifting during the folding process.

The fabric is folded, and then cut,

so it can be checked for any flaws during the folding process.

The fabric is ready to be cut.

After the fabric has been cut,

the folds are tidied,

the fabric needs to be very uniform.

The fabric is then slid into a 4 ml. clear plastic sleeve.

The sides of the sleeve are taped, to tighten the sleeve,

to keep the fabric from shifting.

One end is closed with a freezer fold, and taped shut,

to protect it from moisture.

The other end is left open.

The fabric is then folded to be weighed.

The specifics of each fabric have to noted on the custom’s form.

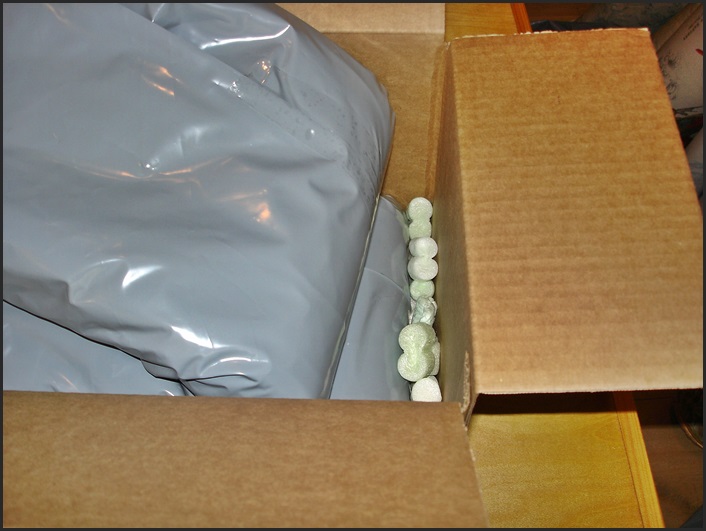

The fabric is then unfolded and the whole is slid into a heavy duty plastic bag,

the sides get folded up and taped,

and it is ready to go into the box.

The closed end of the bag goes into the box,

and then the fabric is folded in a zig-zag fold, with all air being pushed out of it,

as it is folded.

All spaces not filled by the fabric gets filled with bubbles

to keep the box from being crushed while in transit.

After as much air as possible has been pushed out of the clear sleeve,

the inner bag gets sealed with a freezer fold, and is taped shut.

Then the outer bag is sealed as well.

Any open spaces are filled with bubbles, the box is closed, and securely taped for shipping.

_______________________________________

When a bolt is to be shipped the process is similar.

First the fabric is measured

and rolled onto a core.

The fabric gets weighed, and wrapped in a clear plastic sleeve.

The fabric roll is then double bagged in heavy shipping bags.

The outside bags get tapped securely,

and the fabric is ready to be shipped!